Contract production: Benefit from our experience

While we manufacture complete machines, we are also happy to undertake contract production jobs.

The following production facilities are available:

Laser cutting:

Sheet metal format for laser cutting: max. 4000 x 2000 mm

Sheet metal thickness:

– Steel sheets: max. 25 mm

– Stainless steel sheets: max. 15 mm

– Aluminum steel sheets: max. 10 mm

Extensive sheet storage for all common formats and sheet thicknesses

We use nitrogen for the cutting process, thereby ensuring a completely oxide-free cut

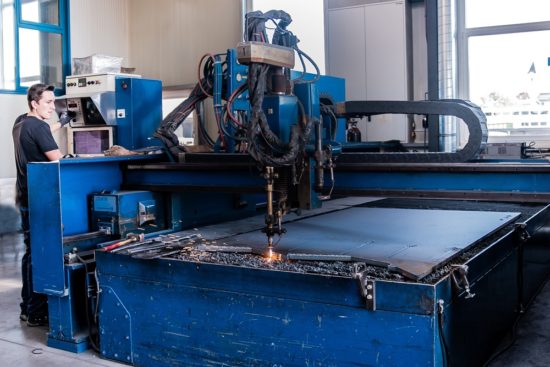

Flame cutting:

Sheet format for oxyacetylene cutting: 4000 x 2000 mm

Sheet metal thickness: up to 100 mm in stock

Sheet edging:

Edge length: up to 4000 mm

Pressing force: 320 t

Sheet roll bending:

Max. finished tube length: 2000 mm

Max. sheet metal thickness: 10 mm

Profile roll bending:

Roll bending of round and shaped tubes, angle steel, a flat steel, I-beams and U-beams

Turned parts:

Series production of turned parts

Maximum size: ø 360 x 500 mm

Welding with robots:

Robot I:

Working range: travel of 8 m

Rotating manipulator for bulky parts up to a length of 5.5 m and a diameter of 2.8 m,

Tilt and turn table

Robot II:

With shuffle table for small parts

Manual welding:

All employees working in the steel construction unit are qualified welders as per

AUSTRIAN STANDARD EN 287-1:2004

Painting:

Continuous paint shop consisting of washing, painting and drying cabins. The ready-welded parts in the steel construction unit are picked up by the conveyor system and degreased in the washing cabin. They are then conveyed to the paint cabin and painted. The parts move from the drying cabin into the assembly area and are then available for final assembly. The conveyor system with electronic lifting gear guarantees a rapid throughput of components.

Max. component size: 2.5 x 2.5 x 10 m

Max. component weight: 3.2 t

Electrical and hydraulic assembly:

The individual components of the new machines are assembled by the employees of the company Stoiber. Everything is done in-house: from electrical installation to pneumatic and hydraulic installation. Each machine is then subjected to a functional test.

Large systems are installed and put into operation directly at the customer site.