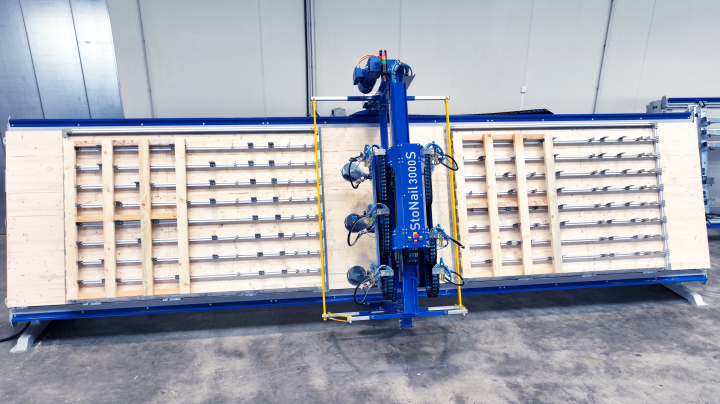

StoNail 5000 - Gantry nailing machine

The StoNail 5000 combines the proven design of the StoNail 3000 with the high flexibility, speed, and advanced programmability of the StoNail 7000.

This highly flexible nailing machine is specifically designed for the production of skid and squared timber pallets in a wide variety of sizes and designs. Thanks to its modular design, the machine size can be individually adapted to specific production requirements. For the production of small pallets, the system allows alternating work at two stations, while for large pallets, the entire working area of the machine can be utilized. In addition, the height-adjustable nailing bridge ensures maximum adaptability and even allows the production of crate parts. The system automatically calculates the shortest and fastest route for nailing the pallet based on the programmed pallet.

General Benefits:

• Modularity: Adaptable machine length and configuration to meet specific production requirements

• Flexibility: Suitable for small pallets (two stations simultaneously) and large pallets (full work area)

• Automation: The machine optimizes the work process by automatically calculating the most efficient and fastest nailing path

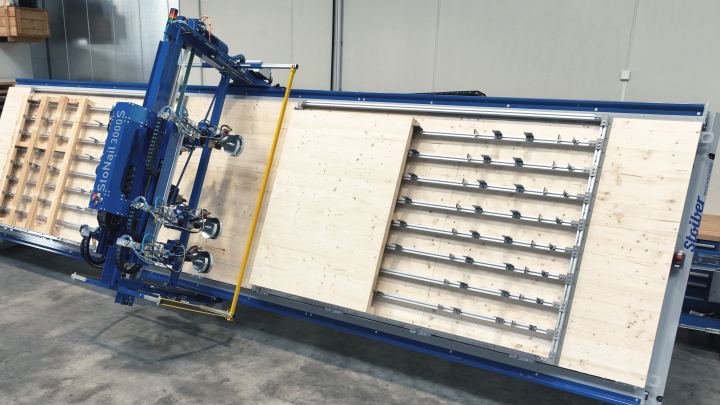

Nailing table with nailing bridge:

- Construction:

- Robust frame with a 65° tilt angle for ergonomic working

- Machine length: approx. 8500 mm (extendable/shortenable by 2000 mm or according to customer requirements)

- Working area:

- 1 pallet: max. 6000 x 1700 mm

- 2 pallets: max. 2500 x 1700 mm per pallet

- Stop system:

- Parallel adjustable double C-rails

- Manually adjustable stops for underpinnings, cross-beams, and deck boards

- Riveting plates can be used in all positions

- Prefabricated skids

- Optional special equipment with plywood panels for custom templates

- Optional aluminum clamping system

- Nailing bridge:

- Frequency-controlled for positioning the nail guns

- Equipped with 6 nailing units including feed cylinder, nailer holder, trigger, and nailer shoes for limiting the driving depth

- Manual Quick adjustment of the nailing unit for different pallet sizes

- Safety features such as collision monitoring (the retraction of the feed cylinder is constantly monitored)

- Start button directly on the nailing bridge

Nail guns:

- Type: Depending on customer requirements (Bea, Bostitch, Max, Fasco, etc.)

- Nail capacity: Up to 90 mm nail length (longer nails upon request)

- Option: Maxi-Coil magazine for up to 1,000 nails

Programming and Control:

- Easy Operation: Intuitive programming including visualization of the product to be nailed (pallets and crates)

- Control: Siemens PLC with touch panel

- Functions:

- Pallet programming directly at the control panel

- Pallet and nail counter; the machine stops as soon as the nails are used up

- Storage of created pallet programs

- Remote maintenance via internet connection

- Multilingual operation (German, English, Czech, Polish)

Safety equipment:

- Emergency stop button on the machine and on the control panel

- Start-up emergency stop on the nailing bridge

- Option: Non-contact safety laser scanner on the nailing bridge

Summary:

The StoNail 5000 is the ideal solution for the production of pallets of any size and complexity. It combines precise technology, high efficiency, and flexible customization options, making it particularly attractive for companies with varying requirements.